JPSPL is Reckoned Amongst the Prominent In RTJ Flange Manufacturers and Exporters Of a Wide Range Of Industrial Ring Type Joint Flanges. These ASME B16.5 RTJ Flange are Designed in Accordance with the Industrial Standards And are Fabricated Using Quality Material. Stainless steel & high nickel alloy RTJ Flange are Known for Excellent Performance, Resistance against corrosion and durability.

These ANSI B16.47 RTJ meet the requirements of various industries like automobile, heavy engineering, railways and pipeline engineering. Available in Standard Specifications, Our Flanges Range Can also be Customized as Per the Requirements of our Clients. Our Carbon Steel RTJ Flange is fabricated with the wall thickness having the same dimensions of the matching pipes. Our Ring Type Joint Plate Flange range is catering to the requirements of various industries and is ideal for use at high pressure, and varied cold or hot temperatures.

| CONST | ITEM | SIZE | SCH/THK | MATERIAL |

|---|---|---|---|---|

| FORGED | SORF | 1/2" TO 24" | 150# TO 1500# | STAINLESS STEEL / CU-NI / DUPLEX / SUPER DUPLEX / HIGH NICKEL ALLOY |

| FORGED | BLRF | 1/2" TO 24" | 150# TO 1500# | STAINLESS STEEL / CU-NI / DUPLEX / SUPER DUPLEX / HIGH NICKEL ALLOY |

| FORGED | SWRF | 1/2" TO 24" | 150# TO 1500# | STAINLESS STEEL / CU-NI / DUPLEX / SUPER DUPLEX / HIGH NICKEL ALLOY |

| FORGED | WNRF | 1/2" TO 24" | 150# TO 1500# | STAINLESS STEEL / CU-NI / DUPLEX / SUPER DUPLEX / HIGH NICKEL ALLOY |

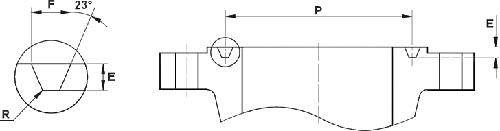

| Class150

NPS |

GrooveNo. | PitchDia

P |

DepthE

Note (1) |

WidthF | Radiusat bottom

R |

| – | R11 | 34.14 | 5.54 | 7.14 | 0.8 |

| – | R12 | 39.67 | 6.35 | 8.74 | 0.8 |

| – | R13 | 42.88 | 6.35 | 8.74 | 0.8 |

| – | R14 | 44.45 | 6.35 | 8.74 | 0.8 |

| 1 | R15 | 47.63 | 6.35 | 8.74 | 0.8 |

| – | R16 | 50.8 | 6.35 | 8.74 | 0.8 |

| 1¼ | R17 | 57.15 | 6.35 | 8.74 | 0.8 |

| – | R18 | 60.33 | 6.35 | 8.74 | 0.8 |

| 1½ | R19 | 65.07 | 6.35 | 8.74 | 0.8 |

| – | R20 | 68.27 | 6.35 | 8.74 | 0.8 |

| – | R21 | 72.23 | 7.92 | 11.91 | 0.8 |

| 2 | R22 | 82.55 | 6.35 | 8.74 | 0.8 |

| – | R23 | 82.55 | 7.92 | 11.91 | 0.8 |

| – | R24 | 95.25 | 7.92 | 11.91 | 0.8 |

| 2½ | R25 | 101.6 | 6.35 | 8.74 | 0.8 |

| – | R26 | 101.6 | 7.92 | 11.91 | 0.8 |

| – | R27 | 107.95 | 7.92 | 11.91 | 0.8 |

| – | R28 | 111.13 | 9.53 | 13.49 | 1.5 |

| 3 | R29 | 114.3 | 6.35 | 8.74 | 0.8 |

| – | R30 | 117.48 | 7.92 | 11.91 | 0.8 |

| – | R31 | 123.83 | 7.92 | 11.91 | 0.8 |

| – | R32 | 127 | 9.53 | 13.49 | 1.5 |

| 3½ | R33 | 131.78 | 6.35 | 8.74 | 0.8 |

| – | R34 | 131.78 | 7.92 | 11.91 | 0.8 |

| – | R35 | 136.53 | 7.92 | 11.91 | 0.8 |

| 4 | R36 | 149.23 | 6.35 | 8.74 | 0.8 |

| – | R37 | 149.23 | 7.92 | 11.91 | 0.8 |

| – | R38 | 157.18 | 11.13 | 16.66 | 1.5 |

| – | R39 | 161.93 | 7.92 | 11.91 | 0.8 |

| 5 | R40 | 171.45 | 6.35 | 8.74 | 0.8 |

| – | R41 | 180.98 | 7.92 | 11.91 | 0.8 |

| – | R42 | 190.5 | 12.7 | 19.84 | 1.5 |

| 6 | R43 | 193.68 | 6.35 | 8.74 | 0.8 |

| – | R44 | 193.68 | 7.92 | 11.91 | 0.8 |

| Material | Grades |

|---|---|

| Stainless Steel | ASTM A182 F Gr.304, 304L, 304H, 309, 310, 316, 316L, 316Ti, 317L, 321, 347, 347H, 904L |

| Duplex Steel | ASTM A182, ASME SA 182 UNS S31803, UNS S32205 (Dual Certified). |

| Super Duplex Steel | ASTM A182, ASME SA 182, UNS S32750, UNS S32760, UNS S32790 |

| High Nickel Alloy | ASTM SB564, SB160, SB472, SB162 Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020) |