We Supply Stub End Up to & Including 12” in Stainless Steel, Super Duplex, Duplex & High Nickel Alloy.

Stub End

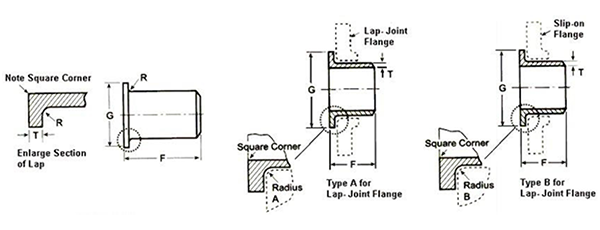

| CONST | ITEM | SIZE | SCH/THK | MATERIAL |

|---|---|---|---|---|

| SMLS/ERW | STUBENDS | 1/2" TO 12" | S10S / 40S / 80S | STAINLESS STEEL / CU-NI / DUPLEX / SUPER DUPLEX / HIGH NICKEL ALLOY |

| Nominal Pipe Size (NPS) |

Outside Diameter at Bevel | OD of Barrel | Length F | Radius of Fillet R | Diameter of Lap G |

|||

| Min. | Max. | ASME | MSS | ASME B16.9& MSS TYPE A | MSS Type B |

|||

| 1/2 | 21.3 | 20.55 | 22.76 | 76.2 | 50.8 | 3.0 | 0.8 | 35.0 |

| 3/4 | 26.7 | 25.88 | 28.09 | 76.2 | 50.8 | 3.0 | 0.8 | 42.9 |

| 1 | 33.4 | 32.61 | 34.95 | 101.6 | 50.8 | 3.0 | 0.8 | 50.8 |

| 1-1/4 | 42.2 | 41.38 | 43.59 | 101.6 | 50.8 | 4.8 | 0.8 | 63.5 |

| 1-1/2 | 48.3 | 47.47 | 49.94 | 101.6 | 50.8 | 6.4 | 0.8 | 73.2 |

| 2 | 60.3 | 59.54 | 62.38 | 152.4 | 63.5 | 7.9 | 0.8 | 91.9 |

| 2-1/2 | 73.0 | 72.24 | 75.34 | 152.4 | 63.5 | 7.9 | 0.8 | 104.6 |

| 3 | 88.9 | 88.11 | 91.34 | 152.4 | 63.5 | 9.7 | 0.8 | 127.0 |

| 3-1/2 | 101.6 | 100.81 | 104.04 | 152.4 | 76.2 | 9.7 | 0.8 | 139.7 |

| 4 | 114.3 | 113.51 | 116.66 | 152.4 | 76.2 | 11.2 | 0.8 | 157.2 |

| 5 | 141.3 | 140.51 | 144.35 | 203.2 | 76.2 | 11.2 | 1.5 | 185.7 |

| 6 | 168.3 | 167.49 | 171.27 | 203.2 | 88.9 | 12.7 | 1.5 | 215.9 |

| 8 | 219.1 | 218.29 | 222.07 | 203.2 | 101.6 | 12.7 | 1.5 | 269.7 |

| 10 | 273.1 | 272.26 | 277.19 | 254.0 | 127.0 | 12.7 | 1.5 | 323.9 |

| 12 | 323.9 | 323.06 | 327.99 | 254.0 | 152.4 | 12.7 | 1.5 | 381.0 |

| 14 | 355.6 | 354.81 | 359.92 | 304.8 | 152.4 | 12.7 | 1.5 | 412.8 |

| 16 | 406.4 | 405.61 | 410.97 | 304.8 | 152.4 | 12.7 | 1.5 | 469.9 |

| 18 | 457.2 | 456.41 | 462.03 | 304.8 | 152.4 | 12.7 | 1.5 | 533.4 |

| 20 | 508.0 | 507.21 | 514.10 | 304.8 | 152.4 | 12.7 | 1.5 | 584.2 |

| 22 | 558.8 | 558.01 | 564.90 | 304.8 | 152.4 | 12.7 | 1.5 | 641.4 |

| 24 | 609.6 | 608.81 | 615.70 | 304.8 | 152.4 | 12.7 | 1.5 | 692.2 |

| O.D | OD Tol | ID Tol | Schedule | Overall Length | Radius of Fillet | Diameter Of Lap | Thickness | ||||||||||||||

| NPS | D | (+) | (-) | (+/-) | 5S | 10 | 10S | 40 | 40S/STD | 80 | 80S/XS | 160 | XXS | Long Pattern / F | Short Pattern / F | Tol | R | Tol | G | Tol | T |

| 1/2'' | 21.3 | 1.6 | 0.8 | 0.8 | 1.65 | 2.11 | 2.11 | 2.77 | 2.77 | 3.73 | 3.73 | 4.78 | 7.47 | 76 | 51 | 2 | 3 | +0,-1 | 35 | +0,-1 | +1.6,-0 |

| 3/4'' | 26.9 | 1.6 | 0.8 | 0.8 | 1.65 | 2.11 | 2.11 | 2.87 | 2.87 | 3.91 | 3.91 | 5.56 | 7.82 | 76 | 51 | 2 | 3 | +0,-1 | 43 | +0,-1 | +1.6,-0 |

| 1'' | 33.4 | 1.6 | 0.8 | 0.8 | 1.65 | 2.77 | 2.77 | 3.38 | 3.38 | 4.55 | 4.55 | 6.35 | 9.09 | 102 | 51 | 2 | 3 | +0,-1 | 51 | +0,-1 | +1.6,-0 |

| 1 1/4'' | 42.6 | 1.6 | 0.8 | 0.8 | 1.65 | 2.77 | 2.77 | 3.56 | 3.56 | 4.85 | 4.85 | 6.35 | 9.70 | 102 | 51 | 2 | 5 | +0,-1 | 64 | +0,-1 | +1.6,-0 |

| 1 1/2'' | 48.3 | 1.6 | 0.8 | 0.8 | 1.65 | 2.77 | 2.77 | 3.68 | 3.68 | 5.08 | 5.08 | 7.14 | 10.15 | 102 | 51 | 2 | 6 | +0,-1 | 73 | +0,-1 | +1.6,-0 |

| 2'' | 60.3 | 1.6 | 0.8 | 0.8 | 1.65 | 2.77 | 2.77 | 3.91 | 3.91 | 5.54 | 5.54 | 8.74 | 11.07 | 152 | 64 | 2 | 8 | +0,-1 | 92 | +0,-1 | +1.6,-0 |

| 2 1/2'' | 73 | 1.6 | 0.8 | 0.8 | 2.11 | 3.05 | 3.05 | 5.16 | 5.16 | 7.01 | 7.01 | 9.35 | 14.02 | 152 | 64 | 2 | 8 | +0,-1 | 105 | +0,-1 | +1.6,-0 |

| 3'' | 88.9 | 1.6 | 1.6 | 1.6 | 2.11 | 3.05 | 3.05 | 5.49 | 5.49 | 7.62 | 7.62 | 11.13 | 15.24 | 152 | 64 | 2 | 10 | +0,-1 | 127 | +0,-1 | +1.6,-0 |

| 3 ½'' | 101.6 | 1.6 | 1.6 | 1.6 | 2.11 | 3.05 | 3.05 | 5.74 | 5.74 | 8.08 | 8.08 | -- | -- | 152 | 76 | 2 | 10 | +0,-1 | 140 | +0,-1 | +1.6,-0 |

| 4'' | 114.3 | 1.6 | 1.6 | 1.6 | 2.11 | 3.05 | 3.05 | 6.02 | 6.02 | 8.56 | 8.56 | 13.49 | 17.12 | 152 | 76 | 2 | 11 | +0,-2 | 157 | +0,-1 | +1.6,-0 |

| 5'' | 141.3 | 2.4 | 1.6 | 1.6 | 2.77 | 3.40 | 3.40 | 6.55 | 6.55 | 9.53 | 9.53 | 15.88 | 19.05 | 203 | 76 | 2 | 11 | +0,-2 | 186 | +0,-1 | +1.6,-0 |

| 6'' | 168.3 | 2.4 | 1.6 | 1.6 | 2.77 | 3.40 | 3.40 | 7.11 | 7.11 | 10.97 | 10.97 | 18.26 | 21.95 | 203 | 89 | 2 | 13 | +0,-2 | 216 | +0,-1 | +1.6,-0 |

| 8'' | 219.1 | 2.4 | 1.6 | 1.6 | 2.77 | 3.76 | 3.76 | 8.18 | 8.18 | 12.70 | 12.70 | 23.01 | 22.23 | 203 | 102 | 2 | 13 | +0,-2 | 270 | +0,-1 | +1.6,-0 |

| 10'' | 273 | 4.0 | 3.2 | 3.2 | 3.40 | 4.19 | 4.19 | 9.27 | 9.27 | 15.09 | 12.70 | 28.58 | 25.40 | 254 | 127 | 2 | 13 | -- | 324 | +0,-1 | -- |

| 12'' | 323.9 | 4.0 | 3.2 | 3.2 | 3.96 | 4.57 | 4.57 | 10.31 | 9.53 | 17.48 | 12.70 | 33.32 | 25.40 | 254 | 152 | 2 | 13 | -- | 381 | +0,-1 | -- |

| 14'' | 355.6 | 4.0 | 3.2 | 3.2 | 3.96 | 6.35 | 4.78 | 11.13 | 9.53 | 19.05 | 12.70 | 35.71 | 35.71 | 305 | 152 | 2 | 13 | -- | 413 | +0,-1 | -- |

| 16'' | 406.4 | 4.0 | 3.2 | 3.2 | 4.19 | 6.35 | 4.78 | 12.70 | 9.53 | 21.44 | 12.70 | 40.49 | 40.49 | 305 | 152 | 2 | 13 | -- | 152 | +0,-1 | -- |

| 18'' | 457 | 4.0 | 3.2 | 3.2 | 4.19 | 6.35 | 4.78 | 14.27 | 9.53 | 23.88 | 12.70 | 45.24 | 45.24 | 305 | 152 | 2 | 13 | -- | 533 | +0,-1 | -- |

| 20'' | 508 | 6.4 | 4.8 | 4.8 | 4.78 | 6.35 | 5.54 | 15.09 | 9.53 | 26.19 | 12.70 | 50.01 | 50.01 | 305 | 152 | 2 | 13 | -- | 584 | +0,-1 | -- |

| 22'' | 559 | 6.4 | 4.8 | 4.8 | 4.78 | 6.35 | 5.54 | -- | 9.53 | 28.58 | 12.70 | 53.98 | 53.97 | 305 | 152 | 2 | 13 | -- | 641 | +0,-1 | -- |

| 24'' | 610 | 6.4 | 4.8 | 4.8 | 5.54 | 6.35 | 6.35 | 17.48 | 9.53 | 30.96 | 12.70 | 59.54 | 59.54 | 305 | 152 | 2 | 13 | -- | 692 | +0,-1 | -- |

Note:

1. Thickness shall not be less than 87.5% of Nominal Wall Thickness

2. All Dimensions are in MM Unless & Otherwise Specified

3. Service conditions and joint construction often dictate stub end length requirements. therefore, the purchaser must specify long or short.

4. Gasket face finish shall be in accordance with ASME B16.5 for Raised face flange.

5. The lap thickness T, Shall Not be less than Nominal pipe wall thickness.

6. When short pattern stub ends are used with large flange in #300 & #600, with most sizes in #900 & higher, and when long pattern stub end are used with large flanges in #1500 & #2500, it may be necessary to increase the length of stub ends in order to avoid covering the weld with the flange. Such increase in length shall be a matter of agreement between the manufacturer and purchaser.

7. When special facings such as tongue & groove or male & female are employed, additional lap thickness must be provided and such additional thickness shall be in addition to (not included in) the basic length, F.

8. These dimensions conform to the radius established for lap joint flanges in ASME B16.5.

9. This dimension conforms to standard machined facings shown in ASME B16.5. The back face of the lap shall be machined to conform to the surface on which it sits, where ring joint facings are to be applied, use dimension K as given in ASME B16.5

| Material | Grades |

|---|---|

| ASTM A403 WP | Gr. 304, 304L, 304H, 309, 310, 316, 316L, 316Ti, 317L, 321, 347, 347H, 904L |

| Super Duplex Steel | ASTM A815, ASME SA 815, UNS S32750, UNS 32760 |

| Duplex Steel | ASTM A815, ASME SA 815 UNS S31803, UNS S32205 |

| Nickel Alloy | ASTM / ASME SB 336 UNS 2200 (NICKEL 200), ASTM / ASME SB 363 , ASTM / ASME SB 366, UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 ) |