We supply Equal and Unequal Tees in Seamless Construction up to 8", Welded in Two Halves Constructions up to 24" and Fabricated up to 48". We Supply Tees in Stainless Steel & High Nickel Alloy. We also manufacture special products under this segments are Lateral Tees, Y-Piece, Cross, Barred Tee & Flow Tee.

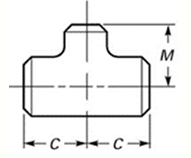

Tee

| CONST | ITEM | SIZE | SCH/THK | MATERIAL |

|---|---|---|---|---|

| SMLS/ERW | Tee | 1/2" TO 8" | S10S / 40S / 80S | STAINLESS STEEL / CU-NI / DUPLEX / SUPER DUPLEX / HIGH NICKEL ALLOY |

| CONST | ITEM | SIZE | SCH/THK | MATERIAL |

|---|---|---|---|---|

| WELDED ( 2 Joints ) |

Tee | 8" TO 16" | S10S/40S/4MM/6MM/8MM/10MM/12MM | STAINLESS STEEL / CU-NI / DUPLEX / SUPER DUPLEX / HIGH NICKEL ALLOY |

Equal Tee

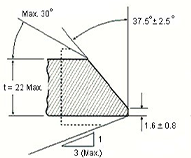

(a) Plain Bevel

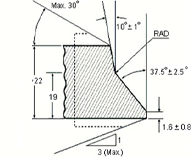

(b) Compound Bevel

| OD | OD Tolerance | ID Tole.. | Schedule | Center to End | Angularity Tolerance | ||||||||||||||

| DN | NPS | D | (+) | (-) | (±) | 5S | 10 | 10S | 40 | 40S/ | 80 | 80S/ | 160 | XXS | Run | M | Height Tolerance | Off Plane | Off angle |

| STD | XS | (C) | (Outlet) | P | Q | ||||||||||||||

| 15 | ½” | 21.3 | 1.6 | 0.8 | 0.8 | 1.65 | 2.11 | 2.11 | 2.77 | 2.77 | 3.73 | 3.73 | 4.78 | 7.47 | 25 | 25 | 2 | 2 | 1 |

| 20 | ¾” | 26.9 | 1.6 | 0.8 | 0.8 | 1.65 | 2.11 | 2.11 | 2.87 | 2.87 | 3.91 | 3.91 | 5.56 | 7.82 | 29 | 29 | 2 | 2 | 1 |

| 25 | 1” | 33.4 | 1.6 | 0.8 | 0.8 | 1.65 | 2.77 | 2.77 | 3.38 | 3.38 | 4.55 | 4.55 | 6.35 | 9.09 | 38 | 38 | 2 | 2 | 1 |

| 32 | 1 ¼” | 42.6 | 1.6 | 0.8 | 0.8 | 1.65 | 2.77 | 2.77 | 3.56 | 3.56 | 4.85 | 4.85 | 6.35 | 9.70 | 48 | 48 | 2 | 2 | 1 |

| 40 | 1 ½” | 48.3 | 1.6 | 0.8 | 0.8 | 1.65 | 2.77 | 2.77 | 3.68 | 3.68 | 5.08 | 5.08 | 7.14 | 10.15 | 57 | 57 | 2 | 2 | 1 |

| 50 | 2” | 60.3 | 1.6 | 0.8 | 0.8 | 1.65 | 2.77 | 2.77 | 3.91 | 3.91 | 5.54 | 5.54 | 8.74 | 11.07 | 64 | 64 | 2 | 2 | 1 |

| 65 | 2 ½” | 73 | 1.6 | 0.8 | 0.8 | 2.11 | 3.05 | 3.05 | 5.16 | 5.16 | 7.01 | 7.01 | 9.35 | 14.02 | 76 | 76 | 2 | 2 | 1 |

| 80 | 3” | 88.9 | 1.6 | 1.6 | 1.6 | 2.11 | 3.05 | 3.05 | 5.49 | 5.49 | 7.62 | 7.62 | 11.13 | 15.24 | 86 | 86 | 2 | 2 | 1 |

| 90 | 3 ½” | 101.6 | 1.6 | 1.6 | 1.6 | 2.11 | 3.05 | 3.05 | 5.74 | 5.74 | 8.08 | 8.08 | --- | --- | 95 | 95 | 2 | 2 | 1 |

| 100 | 4” | 114.3 | 1.6 | 1.6 | 1.6 | 2.11 | 3.05 | 3.05 | 6.02 | 6.02 | 8.56 | 8.56 | 13.49 | 17.12 | 105 | 105 | 2 | 2 | 1 |

| 125 | 5” | 141.3 | 2.4 | 1.6 | 1.6 | 2.77 | 3.40 | 3.40 | 6.55 | 6.55 | 9.53 | 9.53 | 15.88 | 19.05 | 124 | 124 | 2 | 4 | 2 |

| 150 | 6” | 168.3 | 2.4 | 1.6 | 1.6 | 2.77 | 3.40 | 3.40 | 7.11 | 7.11 | 10.97 | 10.97 | 18.26 | 21.95 | 143 | 143 | 2 | 4 | 2 |

| 200 | 8” | 219.1 | 2.4 | 1.6 | 1.6 | 2.77 | 3.76 | 3.76 | 8.18 | 8.18 | 12.70 | 12.70 | 23.01 | 22.23 | 178 | 178 | 2 | 4 | 2 |

| 250 | 10” | 273 | 4.0 | 3.2 | 3.2 | 3.40 | 4.19 | 4.19 | 9.27 | 9.27 | 15.09 | 12.70 | 28.58 | 25.40 | 216 | 216 | 2 | 5 | 3 |

| 300 | 12” | 323.9 | 4.0 | 3.2 | 3.2 | 3.96 | 4.57 | 4.57 | 10.31 | 9.53 | 17.48 | 12.70 | 33.32 | 25.40 | 254 | 254 | 2 | 5 | 3 |

| 350 | 14” | 355.6 | 4.0 | 3.2 | 3.2 | 3.96 | 6.35 | 4.78 | 11.13 | 9.53 | 19.05 | 12.70 | 35.71 | 35.71 | 279 | 279 | 2 | 6 | 3 |

| 400 | 16” | 406.4 | 4.0 | 3.2 | 3.2 | 4.19 | 6.35 | 4.78 | 12.70 | 9.53 | 21.44 | 12.70 | 40.49 | 40.49 | 305 | 305 | 2 | 6 | 3 |

| 450 | 18” | 457 | 4.0 | 3.2 | 3.2 | 4.19 | 6.35 | 4.78 | 14.27 | 9.53 | 23.88 | 12.70 | 45.24 | 45.24 | 343 | 343 | 2 | 10 | 4 |

| 500 | 20” | 508 | 6.4 | 4.8 | 4.8 | 4.78 | 6.35 | 5.54 | 15.09 | 9.53 | 26.19 | 12.70 | 50.01 | 50.01 | 381 | 381 | 2 | 10 | 4 |

| 550 | 22” | 559 | 6.4 | 4.8 | 4.8 | 4.78 | 6.35 | 5.54 | --- | 9.53 | 28.58 | 12.70 | 53.98 | 53.97 | 419 | 419 | 2 | 10 | 4 |

| 600 | 24” | 610 | 6.4 | 4.8 | 4.8 | 5.54 | 6.35 | 6.35 | 17.48 | 9.53 | 30.96 | 12.70 | 59.54 | 59.54 | 432 | 432 | 2 | 10 | 4 |

Note: 1. Thickness shall not be less than 87.5% of Nominal Wall Thickness

2. All Dimensions are in MM Unless & Otherwise Specified.

Unequal Tee

(a) Plain Bevel

(b) Compound Bevel

| D | d | OD | OD Tole. | ID Tole.. | Schedule | Center to End | Angularity Tolerance | |||||||||||||

| NPS | NPS | D | d | (+) | (-) | (±) | 5S | 10 | 10S | 40 | 40S/STD | 80 | 80S/XS | 160 | XXS | C | M | Height Tole. | Off Plane | Off angle |

| P | Q | |||||||||||||||||||

| ½” | 3/8” | 21.3 | 17.3 | 1.6 | 0.8 | 0.8 | 1.65 | 2.11 | 2.11 | 2.77 | 2.77 | 3.73 | 3.73 | 4.78 | 7.47 | 25 | 25 | 2 | 2 | 1 |

| ¼” | 13.7 | 25 | ||||||||||||||||||

| ¾” | ½” | 26.9 | 21.3 | 1.6 | 0.8 | 0.8 | 1.65 | 2.11 | 2.11 | 2.87 | 2.87 | 3.91 | 3.91 | 5.56 | 7.82 | 29 | 29 | 2 | 2 | 1 |

| 3/8” | 17.3 | 29 | ||||||||||||||||||

| 1” | ¾” | 33.4 | 26.9 | 1.6 | 0.8 | 0.8 | 1.65 | 2.77 | 2.77 | 3.38 | 3.38 | 4.55 | 4.55 | 6.35 | 9.09 | 38 | 38 | 2 | 2 | 1 |

| ½” | 21.3 | 38 | ||||||||||||||||||

| 1 ¼” | 1” | 42.6 | 33.4 | 1.6 | 0.8 | 0.8 | 1.65 | 2.77 | 2.77 | 3.56 | 3.56 | 4.85 | 4.85 | 6.35 | 9.7 | 48 | 48 | 2 | 2 | 1 |

| ¾” | 26.9 | 48 | ||||||||||||||||||

| ½” | 21.3 | 48 | ||||||||||||||||||

| 1 ½” | 1 ¼” | 48.3 | 42.6 | 1.6 | 0.8 | 0.8 | 1.65 | 2.77 | 2.77 | 3.68 | 3.68 | 5.08 | 5.08 | 7.14 | 10.15 | 57 | 57 | 2 | 2 | 1 |

| 1” | 33.4 | 57 | ||||||||||||||||||

| ¾” | 26.9 | 57 | ||||||||||||||||||

| ½” | 21.3 | 57 | ||||||||||||||||||

| 2” | 1 ½” | 60.3 | 48.3 | 1.6 | 0.8 | 0.8 | 1.65 | 2.77 | 2.77 | 3.91 | 3.91 | 5.54 | 5.54 | 8.74 | 11.07 | 64 | 60 | 2 | 2 | 1 |

| 1 ¼” | 42.6 | 57 | ||||||||||||||||||

| 1” | 33.4 | 51 | ||||||||||||||||||

| ¾” | 26.9 | 44 | ||||||||||||||||||

| 2 ½” | 2” | 73 | 60.3 | 1.6 | 0.8 | 0.8 | 2.11 | 3.05 | 3.05 | 5.16 | 5.16 | 7.01 | 7.01 | 9.35 | 14.02 | 76 | 70 | 2 | 2 | 1 |

| 1 ½” | 48.3 | 67 | ||||||||||||||||||

| 1 ¼” | 42.6 | 64 | ||||||||||||||||||

| 1” | 33.4 | 57 | ||||||||||||||||||

| 3” | 2 ½” | 88.9 | 73 | 1.6 | 1.6 | 1.6 | 2.11 | 3.05 | 3.05 | 5.49 | 5.49 | 7.62 | 7.62 | 11.13 | 15.24 | 86 | 83 | 2 | 2 | 1 |

| 2” | 60.3 | 76 | ||||||||||||||||||

| 1 ½” | 48.3 | 73 | ||||||||||||||||||

| 1 ¼” | 42.6 | 70 | ||||||||||||||||||

| 3 ½” | 3” | 101.6 | 88.9 | 1.6 | 1.6 | 1.6 | 2.11 | 3.05 | 3.05 | 5.74 | 5.74 | 8.08 | 8.08 | --- | --- | 95 | 92 | 2 | 2 | 1 |

| 2 ½” | 73 | 89 | ||||||||||||||||||

| 2” | 60.3 | 83 | ||||||||||||||||||

| 1 ½” | 48.3 | 79 | ||||||||||||||||||

| 4” | 3 ½” | 114.3 | 101.6 | 1.6 | 1.6 | 1.6 | 2.11 | 3.05 | 3.05 | 6.02 | 6.02 | 8.56 | 8.56 | 13.49 | 17.12 | 105 | 102 | 2 | 2 | 1 |

| 3” | 88.9 | 98 | ||||||||||||||||||

| 2 ½” | 73 | 95 | ||||||||||||||||||

| 2” | 60.3 | 89 | ||||||||||||||||||

| 1 ½” | 48.3 | 86 | ||||||||||||||||||

| 5” | 4” | 141.3 | 114.3 | 2.4 | 1.6 | 1.6 | 2.77 | 3.4 | 3.4 | 6.55 | 6.55 | 9.53 | 9.53 | 15.88 | 19.05 | 124 | 117 | 2 | 4 | 2 |

| 3 ½” | 101.6 | 114 | ||||||||||||||||||

| 3” | 88.9 | 111 | ||||||||||||||||||

| 2 ½” | 73 | 108 | ||||||||||||||||||

| 2” | 60.3 | 105 | ||||||||||||||||||

| 6” | 5” | 168.3 | 141.3 | 2.4 | 1.6 | 1.6 | 2.77 | 3.4 | 3.4 | 7.11 | 7.11 | 10.97 | 10.97 | 18.26 | 21.95 | 143 | 137 | 2 | 4 | 2 |

| 4” | 114.3 | 130 | ||||||||||||||||||

| 3 ½” | 101.6 | 127 | ||||||||||||||||||

| 3” | 88.9 | 124 | ||||||||||||||||||

| 2 ½” | 73 | 121 | ||||||||||||||||||

| 8” | 6” | 219.1 | 168.3 | 2.4 | 1.6 | 1.6 | 2.77 | 3.76 | 3.76 | 8.18 | 8.18 | 12.7 | 12.7 | 23.01 | 22.23 | 178 | 168 | 2 | 4 | 2 |

| 5” | 141.3 | 162 | ||||||||||||||||||

| 4” | 114.3 | 156 | ||||||||||||||||||

| 3 ½” | 101.6 | 152 | ||||||||||||||||||

| 10” | 8” | 273 | 219.1 | 4 | 3.2 | 3.2 | 3.4 | 4.19 | 4.19 | 9.27 | 9.27 | 15.09 | 12.7 | 28.58 | 25.4 | 216 | 203 | 2 | 5 | 3 |

| 6” | 168.3 | 194 | ||||||||||||||||||

| 5” | 141.3 | 191 | ||||||||||||||||||

| 4” | 114.3 | 184 | ||||||||||||||||||

| 12” | 10” | 323.9 | 273 | 4 | 3.2 | 3.2 | 3.96 | 4.57 | 4.57 | 10.31 | 9.53 | 17.48 | 12.7 | 33.32 | 25.4 | 254 | 241 | 2 | 5 | 3 |

| 8” | 219.1 | 229 | ||||||||||||||||||

| 6” | 168.3 | 219 | ||||||||||||||||||

| 5” | 141.3 | 216 | ||||||||||||||||||

| 14” | 12” | 355.6 | 323.9 | 4 | 3.2 | 3.2 | 3.96 | 6.35 | 4.78 | 11.13 | 9.53 | 19.05 | 12.7 | 35.71 | 35.71 | 279 | 270 | 2 | 6 | 3 |

| 10” | 273 | 257 | ||||||||||||||||||

| 8” | 219.1 | 248 | ||||||||||||||||||

| 6” | 168.3 | 238 | ||||||||||||||||||

| 16” | 14” | 406.4 | 355.6 | 4 | 3.2 | 3.2 | 4.19 | 6.35 | 4.78 | 12.7 | 9.53 | 21.44 | 12.7 | 40.49 | 40.49 | 305 | 305 | 2 | 6 | 3 |

| 12” | 323.9 | 295 | ||||||||||||||||||

| 10” | 273 | 283 | ||||||||||||||||||

| 8” | 219.1 | 273 | ||||||||||||||||||

| 6” | 168.3 | 264 | ||||||||||||||||||

| 18” | 16” | 457 | 406.4 | 4 | 3.2 | 3.2 | 4.19 | 6.35 | 4.78 | 14.27 | 9.53 | 23.88 | 12.7 | 45.24 | 45.24 | 343 | 330 | 2 | 10 | 4 |

| 14” | 355.6 | 330 | ||||||||||||||||||

| 12” | 323.9 | 321 | ||||||||||||||||||

| 10” | 273 | 308 | ||||||||||||||||||

| 8” | 219.1 | 298 | ||||||||||||||||||

| 20” | 18” | 508 | 457 | 6.4 | 4.8 | 4.8 | 4.78 | 6.35 | 5.54 | 15.09 | 9.53 | 26.19 | 12.7 | 50.01 | 50.01 | 381 | 368 | 2 | 10 | 4 |

| 16” | 406.4 | 356 | ||||||||||||||||||

| 14” | 355.6 | 356 | ||||||||||||||||||

| 12” | 323.9 | 346 | ||||||||||||||||||

| 10” | 273 | 333 | ||||||||||||||||||

| 8” | 219.1 | 324 | ||||||||||||||||||

| 22” | 20” | 559 | 508 | 6.4 | 4.8 | 4.8 | 4.78 | 6.35 | 5.54 | --- | 9.53 | 28.58 | 12.7 | 53.98 | 53.97 | 419 | 406 | 2 | 10 | 4 |

| 18” | 457 | 394 | ||||||||||||||||||

| 16” | 406.4 | 381 | ||||||||||||||||||

| 14” | 355.6 | 381 | ||||||||||||||||||

| 12” | 323.9 | 371 | ||||||||||||||||||

| 10” | 273 | 359 | ||||||||||||||||||

| 24” | 22” | 610 | 559 | 6.4 | 4.8 | 4.8 | 5.54 | 6.35 | 6.35 | 17.48 | 9.53 | 30.96 | 12.7 | 59.54 | 59.54 | 432 | 432 | 2 | 10 | 4 |

| 20” | 508 | 432 | ||||||||||||||||||

| 18” | 457 | 419 | ||||||||||||||||||

| 16” | 406.4 | 406 | ||||||||||||||||||

| 14” | 355.6 | 406 | ||||||||||||||||||

| 12” | 323.9 | 397 | ||||||||||||||||||

| 10” | 273 | 384 | ||||||||||||||||||

Note:

1. Thickness shall not be less than 87.5% of Nominal Wall Thickness

2. All Dimensions are in MM Unless & Otherwise Specified.

| Material | Grades |

|---|---|

| ASTM A403 WP | Gr. 304, 304L, 304H, 309, 310, 316, 316L, 316Ti, 317L, 321, 347, 347H, 904L |

| Super Duplex Steel | ASTM A815, ASME SA 815, UNS S32750, UNS 32760 |

| Duplex Steel | ASTM A815, ASME SA 815 UNS S31803, UNS S32205 |

| Nickel Alloy | ASTM / ASME SB 336 UNS 2200 (NICKEL 200), ASTM / ASME SB 363 , ASTM / ASME SB 366, UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276( HASTELLOY C 276 ) |