We Supply End Caps Up to 16” in Stainless Steel, Super Duplex, Duplex, High Nickel Alloy.

Pipe Cap

| CONST | ITEM | SIZE | SCH/THK | MATERIAL |

|---|---|---|---|---|

| SMLS | CAPS | 1/2" TO 24" | S10S/40S/80S | STAINLESS STEEL / CU-NI / DUPLEX / SUPER DUPLEX / HIGH NICKEL ALLOY |

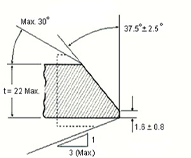

(a) Plain Bevel

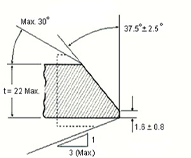

(b) Compound Bevel

| OD | OD Tolerance | ID Tolerance. | Schedule | Length (Note 3) | Wall Thickness for Length | Length (Note 4) | Length of cap Tolerance | |||||||||||

| DN | NPS | D | (+) | (-) | (±) | 5S | 10 | 10S | 40 | 40S/ | 80 | 80S/ | 160 | XXS | (E) | E | E1 | |

| STD | XS | |||||||||||||||||

| 15 | ½” | 21.3 | 1.6 | 0.8 | 0.8 | 1.65 | 2.11 | 2.11 | 2.77 | 2.77 | 3.73 | 3.73 | 4.78 | 7.47 | 25 | 4.57 | 25 | 3 |

| 20 | ¾” | 26.9 | 1.6 | 0.8 | 0.8 | 1.65 | 2.11 | 2.11 | 2.87 | 2.87 | 3.91 | 3.91 | 5.56 | 7.82 | 25 | 3.81 | 25 | 3 |

| 25 | 1” | 33.4 | 1.6 | 0.8 | 0.8 | 1.65 | 2.77 | 2.77 | 3.38 | 3.38 | 4.55 | 4.55 | 6.35 | 9.09 | 38 | 4.17 | 38 | 3 |

| 32 | 1 ¼” | 42.6 | 1.6 | 0.8 | 0.8 | 1.65 | 2.77 | 2.77 | 3.56 | 3.56 | 4.85 | 4.85 | 6.35 | 9.7 | 38 | 4.83 | 38 | 3 |

| 40 | 1 ½” | 48.3 | 1.6 | 0.8 | 0.8 | 1.65 | 2.77 | 2.77 | 3.68 | 3.68 | 5.08 | 5.08 | 7.14 | 10.15 | 38 | 5.08 | 38 | 3 |

| 50 | 2” | 60.3 | 1.6 | 0.8 | 0.8 | 1.65 | 2.77 | 2.77 | 3.91 | 3.91 | 5.54 | 5.54 | 8.74 | 11.07 | 38 | 5.59 | 44 | 3 |

| 65 | 2 ½” | 73 | 1.6 | 0.8 | 0.8 | 2.11 | 3.05 | 3.05 | 5.16 | 5.16 | 7.01 | 7.01 | 9.35 | 14.02 | 38 | 7.11 | 51 | 3 |

| 80 | 3” | 88.9 | 1.6 | 1.6 | 1.6 | 2.11 | 3.05 | 3.05 | 5.49 | 5.49 | 7.62 | 7.62 | 11.13 | 15.24 | 51 | 7.62 | 64 | 3 |

| 90 | 3 ½” | 101.6 | 1.6 | 1.6 | 1.6 | 2.11 | 3.05 | 3.05 | 5.74 | 5.74 | 8.08 | 8.08 | --- | --- | 64 | 8.13 | 76 | 3 |

| 100 | 4” | 114.3 | 1.6 | 1.6 | 1.6 | 2.11 | 3.05 | 3.05 | 6.02 | 6.02 | 8.56 | 8.56 | 13.49 | 17.12 | 64 | 8.64 | 76 | 3 |

| 125 | 5” | 141.3 | 2.4 | 1.6 | 1.6 | 2.77 | 3.4 | 3.4 | 6.55 | 6.55 | 9.53 | 9.53 | 15.88 | 19.05 | 76 | 9.65 | 89 | 6 |

| 150 | 6” | 168.3 | 2.4 | 1.6 | 1.6 | 2.77 | 3.4 | 3.4 | 7.11 | 7.11 | 10.97 | 10.97 | 18.26 | 21.95 | 89 | 10.92 | 102 | 6 |

| 200 | 8” | 219.1 | 2.4 | 1.6 | 1.6 | 2.77 | 3.76 | 3.76 | 8.18 | 8.18 | 12.7 | 12.7 | 23.01 | 22.23 | 102 | 12.7 | 127 | 6 |

| 250 | 10” | 273 | 4 | 3.2 | 3.2 | 3.4 | 4.19 | 4.19 | 9.27 | 9.27 | 15.09 | 12.7 | 28.58 | 25.4 | 127 | 12.7 | 152 | 6 |

| 300 | 12” | 323.9 | 4 | 3.2 | 3.2 | 3.96 | 4.57 | 4.57 | 10.31 | 9.53 | 17.48 | 12.7 | 33.32 | 25.4 | 152 | 12.7 | 178 | 6 |

| 350 | 14” | 355.6 | 4 | 3.2 | 3.2 | 3.96 | 6.35 | 4.78 | 11.13 | 9.53 | 19.05 | 12.7 | 35.71 | 35.71 | 165 | 12.7 | 191 | 6 |

| 400 | 16” | 406.4 | 4 | 3.2 | 3.2 | 4.19 | 6.35 | 4.78 | 12.7 | 9.53 | 21.44 | 12.7 | 40.49 | 40.49 | 178 | 12.7 | 203 | 6 |

| 450 | 18” | 457 | 4 | 3.2 | 3.2 | 4.19 | 6.35 | 4.78 | 14.27 | 9.53 | 23.88 | 12.7 | 45.24 | 45.24 | 203 | 12.7 | 229 | 6 |

| 500 | 20” | 508 | 6.4 | 4.8 | 4.8 | 4.78 | 6.35 | 5.54 | 15.09 | 9.53 | 26.19 | 12.7 | 50.01 | 50.01 | 229 | 12.7 | 254 | 6 |

| 550 | 22” | 559 | 6.4 | 4.8 | 4.8 | 4.78 | 6.35 | 5.54 | --- | 9.53 | 28.58 | 12.7 | 53.98 | 53.97 | 254 | 12.7 | 254 | 6 |

| 600 | 24” | 610 | 6.4 | 4.8 | 4.8 | 5.54 | 6.35 | 6.35 | 17.48 | 9.53 | 30.96 | 12.7 | 59.54 | 59.54 | 267 | 12.7 | 305 | 6 |

Note:

1. Thickness shall not be less than 87.5% of Nominal Wall Thickness

2. All Dimensions are in MM Unless & Otherwise Specified.

3. The Length E applies for thickness not exceeding that given in column “Limiting wall thickness for Length E.

4. The Length E1 applies for thickness greater than that given in column “Limiting wall thickness for Length E.

General Note: The shape of these cap shall be ellipsoidal and shall conform to the requirement given in the ASME Boiler & Pressure Vessel Code.

| Material | Grades |

|---|---|

| ASTM A403 WP | Gr. 304, 304L, 304H, 309, 310, 316, 316L, 316Ti, 317L, 321, 347, 347H, 904L |

| Super Duplex Steel | ASTM A815, ASME SA 815, UNS S32750, UNS 32760 |

| Duplex Steel | ASTM A815, ASME SA 815 UNS S31803, UNS S32205 |

| Nickel Alloy | ASTM / ASME SB 336 UNS 2200 (NICKEL 200), ASTM / ASME SB 363 , ASTM / ASME SB 366, UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 ) |