We supply Long Radius and Short Radius Elbows in Seamless Construction up to 12", Welded in Two Halve Constructions up to 24". JPSPL is having latest Mandrel Machines to cater High Wall Thickness Stainless Steel & High Nickel Alloy Elbow.

Our Facility allow us to Manufacture Elbows up to 180° & 90° Long Radius up to 12". Our 500 Ton Conventional Press Machines can form Thickness up to 16mm which enhance our Welded Elbow Production range. Miter Bend, Return Elbow U - Bends, are the type of various Special Products under this segment.

Stainless Steel Elbow

| CONST | ITEM | SIZE | SCH/THK | MATERIAL |

|---|---|---|---|---|

| SMLS/ERW | Elbow | 1/2" TO 12" | S10S / 40S / 80S | STAINLESS STEEL / CU-NI / DUPLEX / SUPER DUPLEX / HIGH NICKEL ALLOY |

| CONST | ITEM | SIZE | SCH/THK | MATERIAL |

|---|---|---|---|---|

| WELDED ( 2 Joints ) |

Elbow | 8" TO 24" | S10S/40S/4MM/6MM/8MM/10MM/12MM | STAINLESS STEEL / CU-NI / DUPLEX / SUPER DUPLEX / HIGH NICKEL ALLOY |

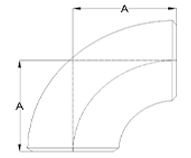

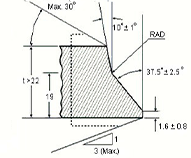

90 Long/Short Radius Elbow

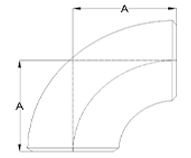

45 Long Radius Elbow

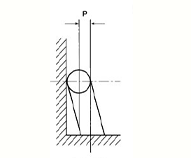

Off Plan P

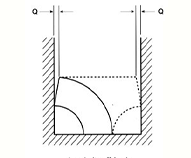

Angularity off Angle Q

(a) Plain Bevel

(b) Compound Bevel

| OD | OD Tolerance | ID Tolerance. | Schedule | (Center to End) | Angularity Tolerance | |||||||||||||||

| Long | Short | Height Tolerance | Off Plane | Off angle | ||||||||||||||||

| 90° | 45° | 90° | ||||||||||||||||||

| DN | NPS | D | (+) | (-) | (±) | 5S | 10 | 10S | 40 | 40S/ | 80 | 80S/ | 160 | XXS | A | B | A | (±) | P | Q |

| STD | XS | |||||||||||||||||||

| 15 | ½” | 21.3 | 1.6 | 0.8 | 0.8 | 1.65 | 2.11 | 2.11 | 2.77 | 2.77 | 3.73 | 3.73 | 4.78 | 7.47 | 38 | 16 | --- | 2 | 2 | 1 |

| 20 | ¾” | 26.9 | 1.6 | 0.8 | 0.8 | 1.65 | 2.11 | 2.11 | 2.87 | 2.87 | 3.91 | 3.91 | 5.56 | 7.82 | 38 | 19 | --- | 2 | 2 | 1 |

| 25 | 1” | 33.4 | 1.6 | 0.8 | 0.8 | 1.65 | 2.77 | 2.77 | 3.38 | 3.38 | 4.55 | 4.55 | 6.35 | 9.09 | 38 | 22 | 25 | 2 | 2 | 1 |

| 32 | 1 ¼” | 42.6 | 1.6 | 0.8 | 0.8 | 1.65 | 2.77 | 2.77 | 3.56 | 3.56 | 4.85 | 4.85 | 6.35 | 9.7 | 48 | 25 | 32 | 2 | 2 | 1 |

| 40 | 1 ½” | 48.3 | 1.6 | 0.8 | 0.8 | 1.65 | 2.77 | 2.77 | 3.68 | 3.68 | 5.08 | 5.08 | 7.14 | 10.15 | 57 | 29 | 38 | 2 | 2 | 1 |

| 50 | 2” | 60.3 | 1.6 | 0.8 | 0.8 | 1.65 | 2.77 | 2.77 | 3.91 | 3.91 | 5.54 | 5.54 | 8.74 | 11.07 | 76 | 35 | 51 | 2 | 2 | 1 |

| 65 | 2 ½” | 73 | 1.6 | 0.8 | 0.8 | 2.11 | 3.05 | 3.05 | 5.16 | 5.16 | 7.01 | 7.01 | 9.35 | 14.02 | 95 | 44 | 64 | 2 | 2 | 1 |

| 80 | 3” | 88.9 | 1.6 | 1.6 | 1.6 | 2.11 | 3.05 | 3.05 | 5.49 | 5.49 | 7.62 | 7.62 | 11.13 | 15.24 | 114 | 51 | 76 | 2 | 2 | 1 |

| 90 | 3 ½” | 101.6 | 1.6 | 1.6 | 1.6 | 2.11 | 3.05 | 3.05 | 5.74 | 5.74 | 8.08 | 8.08 | --- | --- | 133 | 57 | 81 | 2 | 2 | 1 |

| 100 | 4” | 114.3 | 1.6 | 1.6 | 1.6 | 2.11 | 3.05 | 3.05 | 6.02 | 6.02 | 8.56 | 8.56 | 13.49 | 17.12 | 152 | 64 | 102 | 2 | 2 | 1 |

| 125 | 5” | 141.3 | 2.4 | 1.6 | 1.6 | 2.77 | 3.4 | 3.4 | 6.55 | 6.55 | 9.53 | 9.53 | 15.88 | 19.05 | 190 | 79 | 127 | 2 | 4 | 2 |

| 150 | 6” | 168.3 | 2.4 | 1.6 | 1.6 | 2.77 | 3.4 | 3.4 | 7.11 | 7.11 | 10.97 | 10.97 | 18.26 | 21.95 | 229 | 95 | 152 | 2 | 4 | 2 |

| 200 | 8” | 219.1 | 2.4 | 1.6 | 1.6 | 2.77 | 3.76 | 3.76 | 8.18 | 8.18 | 12.7 | 12.7 | 23.01 | 22.23 | 305 | 127 | 203 | 2 | 4 | 2 |

| 250 | 10” | 273 | 4 | 3.2 | 3.2 | 3.4 | 4.19 | 4.19 | 9.27 | 9.27 | 15.09 | 12.7 | 28.58 | 25.4 | 381 | 159 | 254 | 2 | 5 | 3 |

| 300 | 12” | 323.9 | 4 | 3.2 | 3.2 | 3.96 | 4.57 | 4.57 | 10.31 | 9.53 | 17.48 | 12.7 | 33.32 | 25.4 | 457 | 190 | 305 | 2 | 5 | 3 |

| 350 | 14” | 355.6 | 4 | 3.2 | 3.2 | 3.96 | 6.35 | 4.78 | 11.13 | 9.53 | 19.05 | 12.7 | 35.71 | 35.71 | 533 | 222 | 356 | 2 | 6 | 3 |

| 400 | 16” | 406.4 | 4 | 3.2 | 3.2 | 4.19 | 6.35 | 4.78 | 12.7 | 9.53 | 21.44 | 12.7 | 40.49 | 40.49 | 610 | 254 | 406 | 2 | 6 | 3 |

| 450 | 18” | 457 | 4 | 3.2 | 3.2 | 4.19 | 6.35 | 4.78 | 14.27 | 9.53 | 23.88 | 12.7 | 45.24 | 45.24 | 686 | 286 | 457 | 2 | 10 | 4 |

| 500 | 20” | 508 | 6.4 | 4.8 | 4.8 | 4.78 | 6.35 | 5.54 | 15.09 | 9.53 | 26.19 | 12.7 | 50.01 | 50.01 | 762 | 318 | 508 | 2 | 10 | 4 |

| 550 | 22” | 559 | 6.4 | 4.8 | 4.8 | 4.78 | 6.35 | 5.54 | --- | 9.53 | 28.58 | 12.7 | 53.98 | 53.97 | 838 | 343 | 559 | 2 | 10 | 4 |

| 600 | 24” | 610 | 6.4 | 4.8 | 4.8 | 5.54 | 6.35 | 6.35 | 17.48 | 9.53 | 30.96 | 12.7 | 59.54 | 59.54 | 914 | 381 | 610 | 2 | 10 | 4 |

Note:

1. Thickness shall not be less than 87.5% of Nominal Wall Thickness

2. All Dimensions are in MM Unless & Otherwise Specified

| Material | Grades |

|---|---|

| ASTM A403 WP | Gr. 304, 304L, 304H, 309, 310, 316, 316L, 316Ti, 317L, 321, 347, 347H, 904L |

| Super Duplex Steel | ASTM A815, ASME SA 815, UNS S32750, UNS 32760 |

| Duplex Steel | ASTM A815, ASME SA 815 UNS S31803, UNS S32205 |

| Nickel Alloy | ASTM / ASME SB 336 UNS 2200 (NICKEL 200), ASTM / ASME SB 363 , ASTM / ASME SB 366, UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 ) |